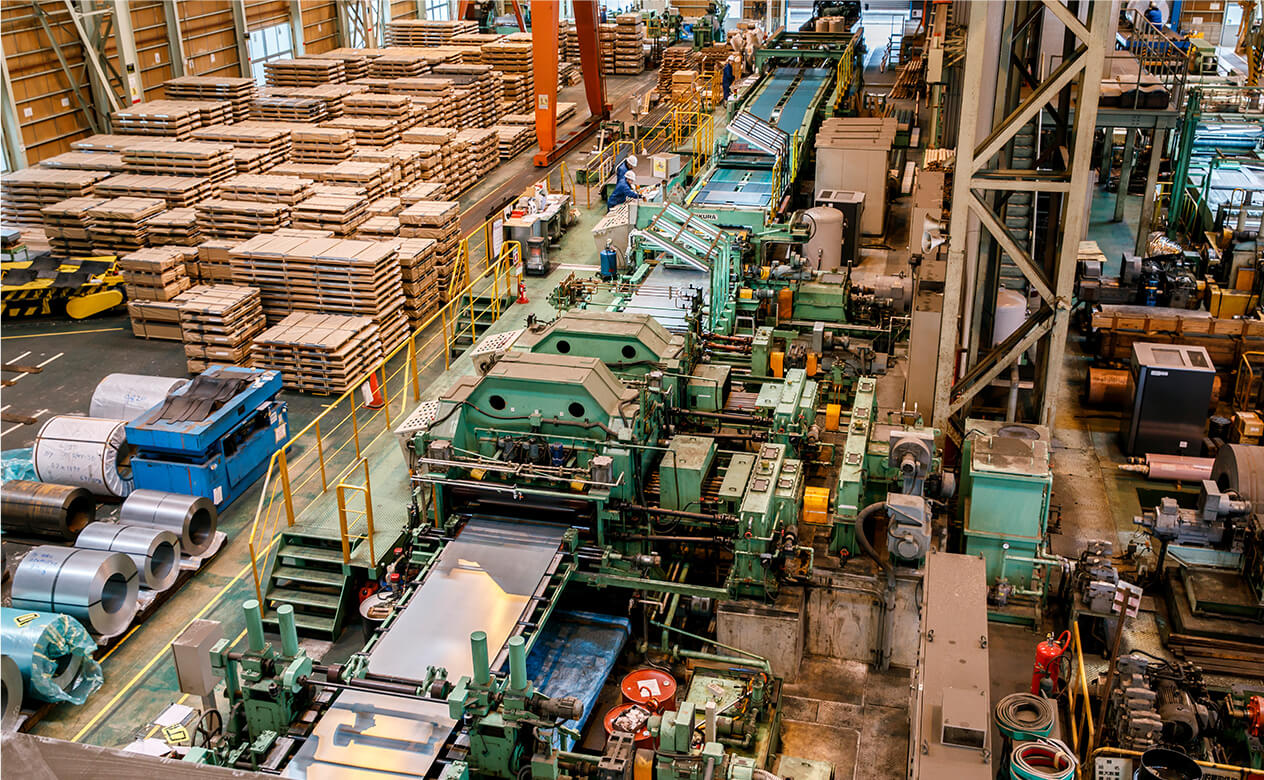

Senboku Center

The Senboku Center provides primary fabrication for a broad array of steel sheet materials

and supplies them to customers on a just-in-time basis.

1,550 mm and 1,850 mm slitters

Leveler line

75-ton mechanical press brake

Floor plate manufacturing line

Mini-slitter line

Mini-leveler line

Mie Center

The Mie Center is equipped with a variety of manufacturing and fabrication equipment

that allows it to provide one-stop manufacturing of building materials and parts.

Slitter line

300-ton Prenotch Forming line

220-ton hydraulic press brake

360-ton hydraulic press

60-ton press

150-ton transfer press

Beam worker

Flat bar manufacturing line

Temporary wall manufacturing line

Forming line

Slitter Specifications

| Factory | Senboku Center | Mie Center | Miyake Factory | ||

|---|---|---|---|---|---|

| Processing range | 1,850 mm slitter | 1,550 mm slitter | Mini slitter | 1,350 mm slitter | 1,600 mm slitter |

| Stock coil thickness(mm) | 0.27〜6.0 | 0.27〜3.2 | 0.27〜2.3 | 0.3〜3.2 | 0.27〜2.3 |

| Stock coil width(mm) | 450〜1,850 | 300〜1,600 | 65〜650 | 90〜1,350 | 610〜1,600 |

| Stock coil weight(t) | MAX25 | MAX20 | MAX5 | MAX20 | MAX20 |

| Stock coil O.D.(mm) | MAXφ2,500 | MAXφ2,000 | MAXφ1,800 | MAXφ2,000 | MAXφ2,000 |

| Stock coil I.D.(mm) | φ508/φ610/φ710/φ762 | φ508/φ610/φ762 | φ508/φ610 | φ508/φ610/φ762 | φ508/φ610 |

| Product width(mm) |

33〜1,850 | 45〜1,550 | 12〜650 | 33〜1,350 | 33.5〜1,524 |

| Max. number of slits | Max. 25 slits for 1.0 mm sheet thickness Max. 7slits for 4.5 mm sheet thickness |

Max. 20 slits for 2.0 mm sheet thickness Max. 8 slits for 3.2 mm sheet thickness |

Max. 15 slits for 0.3 mm sheet thickness Max. 5 slits for 2.3 mm sheet thickness |

Max. 24 slits for 1.6 mm sheet thickness Max. 7 slits for 3.2 mm sheet thickness |

Max. 18 slits for 1.0 mm sheet thickness Max. 13 slits for 1.6 mm sheet thickness |

| Product O.D.(mm) | MAXφ2,500 | MAXφ2,000 | MAXφ1,800 | MAXφ2,000 | MAXφ2,000 |

| Product I.D.(mm) | φ508/φ610/φ710 | φ508/φ610 | φ300/φ508 | φ508/φ610 | φ508 |

| Line speed(mpm) | 90/180 | 70/140 | 150 | 120 | 150 |

Leveler and cold-rolling mill specifications

| Factory | Senboku Center | Miyake Factory | ||

|---|---|---|---|---|

| Processing range | 1,600 mm leveler | Mini-leveler | 1,600 mm leveler | 1,600 mm leveler |

| Stock coil thickness(mm) | 0.3〜4.5 | 0.27〜2.3 | 0.4〜3.2 | 0.2〜3.2 |

| Stock coil width(mm) | 570〜1,600 | 58〜750 | 500〜1,600 | 600〜1,600 |

| Stock coil weight(t) | MAX20 | MAX5 | MAX10 | MAX3 |

| Stock coil O.D.(mm) | MAXφ2,000 | MAXφ1,400 | MAXφ1,600 | MAXφ1,200 |

| Stock coil I.D.(mm) | φ508/φ610/φ762 | φ508 | φ508/φ610/φ710 | φ508/φ610 |

| cut length(mm) | 580〜4,520 | 200〜2,500 | 300〜3,000 | 800〜2,700 |

| Line speed(mpm) | 40/80 | 60 | 60 | 40 |

Building material manufacturing equipment specifications (Mie Center)

| Processing range | No. 1 to No. 5 shaper | Temporary wall manufacturing line | Floor plate manufacturing line | Flat bar manufacturing line |

|---|---|---|---|---|

| Equipment type | Pre-notched shaper | Pre-cut shaper | Pre-cut shaper | Slit flat bar shaper |

| Stock coil thickness(mm) | 1.6~6.0 | 0.8~1.2 | 1.6~3.2 | 1.2~3.2 |

| Stock coil width(mm) | 55~500 | 609 | 19~50 | 500 |

| Stock coil weight(kg) | MAX5(3) | MAX5 | MAX2 | MAX5 |

| Stock coil O.D.(mm) | MAXφ2,000 | MAXφ1,300 | MAXφ1,800 | MAXφ1,600 |

| Stock coil I.D.(mm) | φ508 | φ508 | φ508 | φ508 |

| Cut length(mm) | 1,000~12,000 | 1,000~4,000 | 3,000~6,000 | 50〜3,000 |

| Cut length(mm) | 30~60 | 15 | 60 | 30 |

| Product variants | Light-gauge steel | Temporary wall | 1.6~3.2t×19~50 | Transport conveyor frame |

| Fenceposts, etc. | Flat bar (flat bar and grooved flat bar) | Fittings, etc. |

Product variant

| Beam worker drill × 2 / 220-ton × 4m press brake / 75-ton × 2 m mechanical press / 360-ton hydraulic press /60-ton mechanical press / band saw / Welding robot / Floor plate manufacturing line |

Certification

-

Received ISO 9001 certification.

Design, development, and manufacture of steel sheet and steel building materials for the domestic Japanese market

(Sales Headquarters/Senboku Center/Mie Center)

-

Received JIS certification.

G3350: Light gauge steel sections for general structure (Mie Center)